Thermocouple Links

The following links are thermocouple resources

Type E Thermocouple

(Chromel/Constantan) −270°C to +1000°C (−454°F to +1832°F)

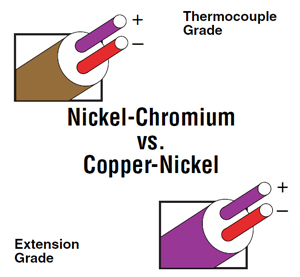

Composed of a positive leg, which is approximately 90% Nickel, 10% Chromium, and a negative leg, which is approximately 55% copper and 45% nickel.

When protected by compacted mineral insulation and appropriate outer sheath, Type E is usable from 0 to 900°C, (32 to 1652°F).

This Thermocouple has the highest EMF output per degree of all recognized thermocouples (68 µV/°C). If the temperature is between 316 to 593°C, (600 to 1100°F), we recommend using type J or N because of aging which can cause drift of 1 to 2°C, (2 to 4°F) in a few hours time. For applications below 0°C, (32°F), special selection of alloys are usually required.

The Type E thermocouple is suitable for use at temperatures up to 900°C (1650°F) in a vacuum, inert, mildly oxidizing or reducing atmosphere. At cryogenic temperatures, the thermocouple is not subject to corrosion. This thermocouple has the highest EMF output per degree of all the commonly used thermocouples and has similar calibration drift to that of Type K so the same precautions are recommended.

Type E Thermocouple ( Chromel/Constantan)

Temperature Range:

•Thermocouple grade wire, −270° to 1,000°C (−454 to 1,832°F)

•Melting Point, 2,230°F (1,220°C)

Accuracy (whichever is greater):

•Standard: ± 0.5C%

•Special Limits of Error: ± 0.25%

Type E Thermocouple Sheath

316 Stainless Steel

Maximum temperature: 1650. Best corrosion resistance of the austenitic stainless steel grades. Widely used in the food and chemical industry. Subject to damaging carbide precipitation in 900°F to 1600°F (482°C to 870°C).

316L Stainless Steel

Maximum temperature: 1650°F (900°C). Same as 316 SST (04) except low carbon version allows for better welding and fabrication.

304 Stainless Steel

Maximum temperature: 1650°F (900°C). Most widely used low temperature sheath material. Extensively used in food, beverage, chemical and other industries where corrosion resistance is required.

Industry: Subject to damaging carbide precipitation in 900 to 1600°F (480 to 870°C) range. Lowest cost corrosion resistant sheath material available.

304L Stainless Steel

Maximum temperature: 1650°F (900?C). Low carbon version of 304 SST (02). Low carbon content allows this material to be welded and heated in the 900 to 1600°F (480 to 870°C) range without damage to corrosion resistance.

310 Stainless Steel

Maximum temperature: 2100?F (1150?C). Mechanical and corrosion resistance, similar to but better than 304 SS. Very good heat resistance.

This alloy contains 25% chromium, 20% nickel. Not as ductile as 304 SS.

321 Stainless Steel

Maximum temperature: 1600°F (870°C). Similar to 304 SS except titanium stabilized for intergranular corrosion.

This alloy is designed to overcome susceptibility to carbon precipitation in the 900 to 1600°F (480 to 870°C) range. Used in aerospace and chemicalapplications.

446 Stainless Steel

Maximum temperature: 2100°F (1150°C). Ferritic stainless steel which has good resistance to sulfurous atmospheres at high temperatures.

Good corrosion resistance to nitric acid, sulfuric acid and most alkalies. 27% chromium content gives this alloy the highest heat resistance of any ferritic stainless steel.

Inconel 600

Maximum temperature: 2150°F (1175°C). Most widely used thermocouple sheath material. Good high temperature strength, corrosion resistance, resistance to chloride-ion stress corrosion cracking and oxidation resistance to high temperatures.

Do not use in sulfur bearing environments. Good in nitriding environments.

Inconel 601

Maximum temperature: 2150°F (1175°C) continuous, 2300°F (1260°C) intermittent. Similar to Alloy 600 with the addition of aluminum for outstanding oxidation resistance. Designed for high temperature corrosion resistance.

This material is good in carburizing environments, and has good creep rupture strength. Do not use in vacuum furnaces! Susceptible to intergranular attack by prolonged heating in 1000 to 1400°F (540 to 760°C) temperature range.

Inconel 800

Maximum temperature: 2000°F (1095°C). Widely used as heater sheath material. Minimal use in thermocouples. Superior to Alloy 600 in sulfur, cyanide salts and fused neutral salts.

Susceptible to intergranular attack in some applications by exposure to the temperature range of 1000 to 1400°F (540 to 7607deg C).